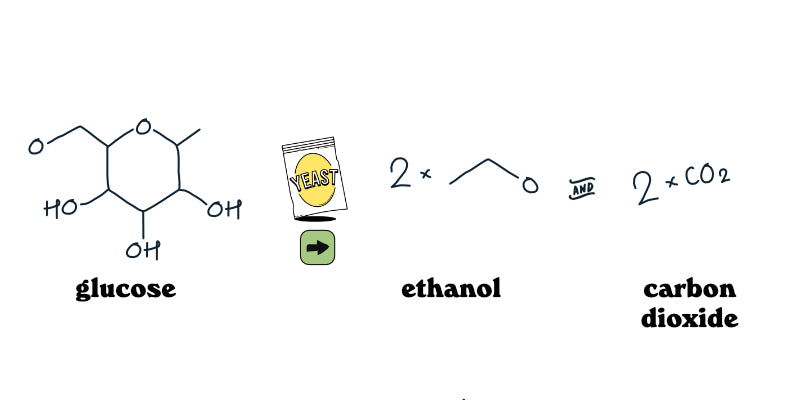

Now we get to the alcohol making. Fermentation is the process by which the yeast converts glucose into alcohol. The more sugars that are in the Wort, the higher the ABV (alcohol content).

As well as producing alcohol, the process also produces carbon dioxide which escapes through the airlock and causes that satisfying bubbling sound!

The fermenter must not allow any air to enter, as this can cause contamination. The other consideration is oxygen. Oxygen helps initiate fermentation at the beginning, however if it’s introduced after primary fermentation it may cause the yeast to produce more of the unwanted by-products, affecting the final aroma and taste.

In this step, it’s important to pitch yeast between 18–22ºC, to ensure healthy yeast fermentation and minimise the risk of off-flavours or stress on the yeast.