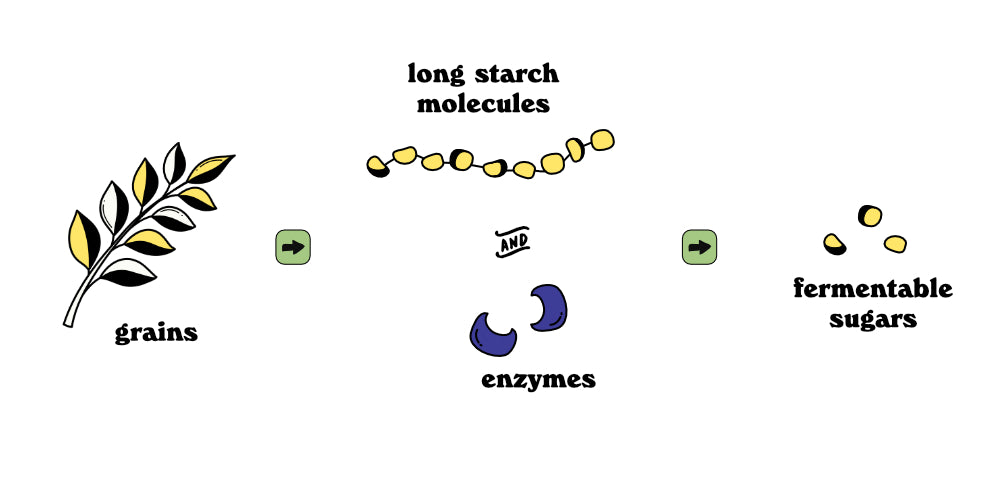

The mash is where the magic begins.

It's the process of soaking crushed grains in hot water, allowing the enzymes to convert starch into fermentable sugars. This creates the sweet concoction known as wort (pronounced ‘Wert’) – the lifeblood of your soon-to-be brew.

This process is important for a number of reasons:

The temperature during the mash is a carefully chosen parameter that influences the beer's character. At lower temperatures (63–68°C), a specific type of enzyme called alpha-amylase is more active. Alpha-amylase breaks down starch molecules into shorter chains of sugars. These shorter chains are highly fermentable by yeast, leading to the production of more sugars. This results in a drier beer with a crisper finish.

On the flip side, higher temperatures (68–74°C) encourage beta-amylase to become more active. Activation of beta-amylase results in the creation of less fermentable sugars, yielding a fuller-bodied beer with a sweeter profile.

Mashing also extracts flavours from the malted grains. Different types of malted grains contribute various flavours to the beer, such as caramel, toffee, chocolate, biscuit, and roasted notes. The temperature and duration of mashing can influence the types and intensity of flavours extracted from the grains.

The colour of the beer is influenced by the type and roast level of the malted grains used in the mash. During mashing, compounds responsible for colour, such as melanoidins and Maillard reaction products, are extracted from the grains. The longer and hotter the mash, the darker the colour of the resulting wort.

Stir the mash thoroughly and often to ensure even distribution of heat and enzymes. Avoid lumps or dry pockets of grains that may hinder proper conversion.

Elevate your game

Some brewers like to use bottled water instead of tap water. This is to produce a more consistent beer each time, as bottled water has a more consistent mineral profile that can influence the flavour profile of your beer. In addition, bottled water typically does not contain chlorine or chloramines, which can be present in some tap water. These chemicals can lead to off flavours in the beer.